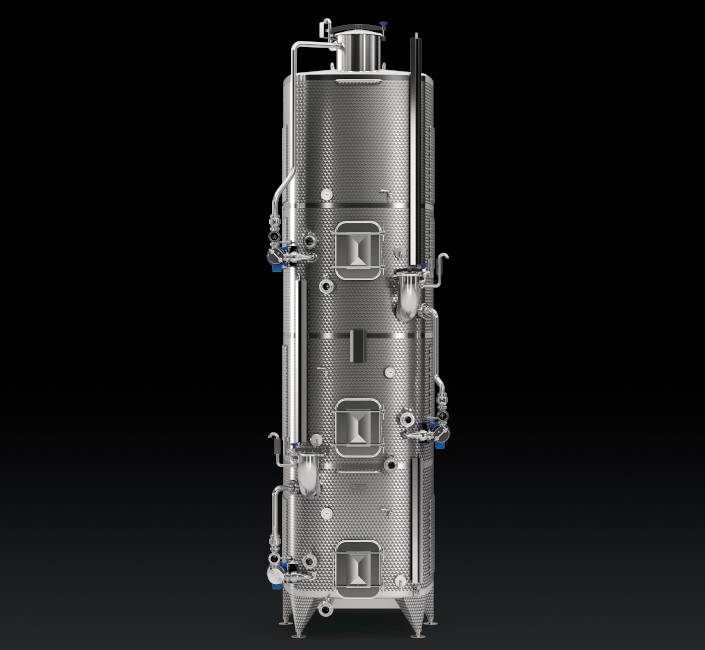

Parallelepiped tank

Our significant experience in parallelepiped stainless steel tanks can provide a competitive advantage in optimising wine-making and storage space.

ROOM FOR CREATIVITY

The parallelepiped structure increases flexibility as even narrow little spaces of a production facility can be exploited. The limit is your imagination, with corners, roofs and raised platforms all coming into play.

MAKE EVERY CENTIMETRE COUNT

Given the same amount of space, parallelepiped tanks provide greater capacity than traditional tanks, and so can optimise space usage in your winery.

PERFORMANCE

In such vats, the heat exchange bands can be attached to the body in a manner that increases performance and thus ensures a more uniform temperature across the product.

CORE UNDER CONTROL

The parallelepiped structure also prevents a “hot core” forming in the liquid, that is, a section where the temperature is above what is desired.

BEYOND ALL LIMITS

There are no construction limits for our parallelepiped tanks. Take the “millipede” – a tank with a capacity exceeding 1,200 hl.